Electrical Wire Connectors Screw 2 Pin 3 Pin Mini EW-M16

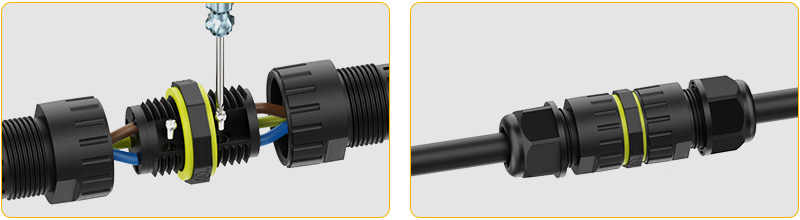

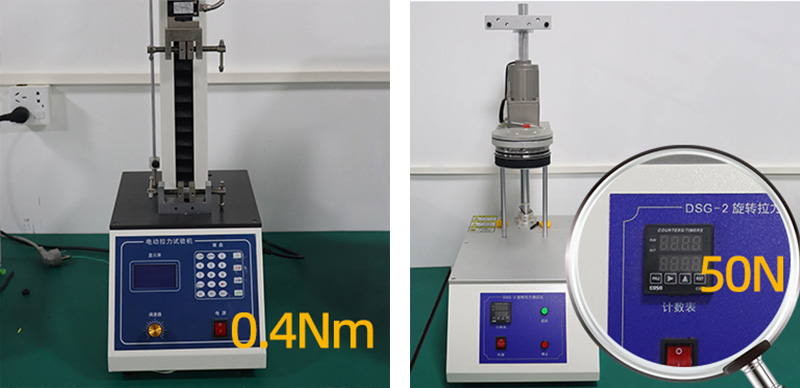

The purpose of locking about electronic products is to prevent loosening of fit parts that may operate under different pressure, temperature or vibration conditions. The effectiveness of the locking is often critical to the security of the system.

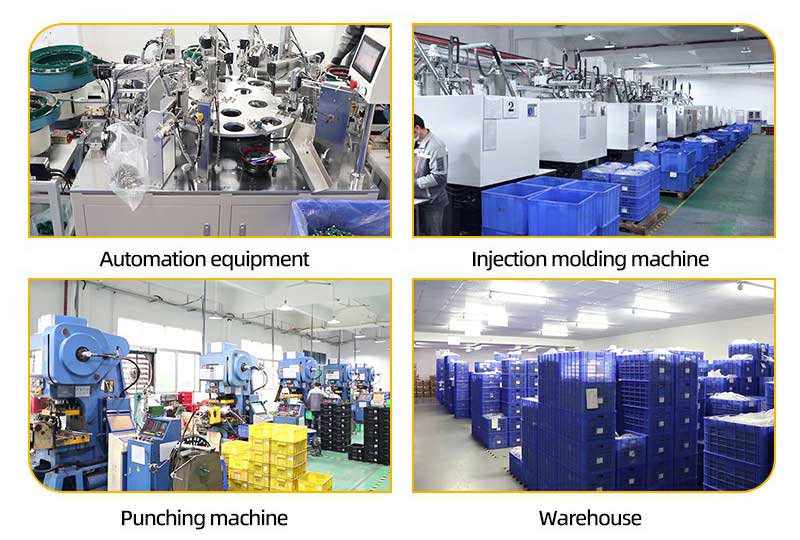

Place of Origin : Guangdong, China

Brand Name : E-WeiChat

Model Number : EW-M16

Application : Electric, such as LED Lighting

Gender : waterproof cable connector

Ampere/Voltage : 17.5A/400V

Wiring Gauge : 0.5~1.5mm^2

Keywords : 2 pin cable connector

Material : PA66&Copper Alloy

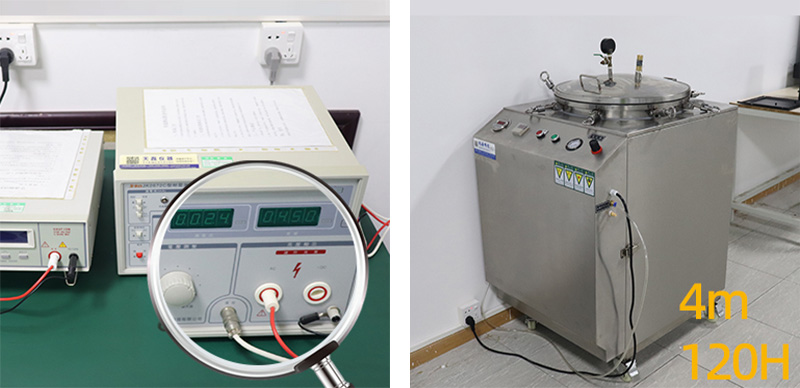

Certificate : UL, TUV, RoHS,CE, SAA

Working temperature : -40℃ - 105℃

Housing : 94V-2 Grade

Wire Diameter : 3.5-7mm/7-10mm

Number of poles : 2 3pin

Home

Home

Related Suggestion

Related Suggestion

Mar 25,2022

Mar 25,2022

Tel

Tel

Email

Email

Address

Address